Home>Products>Original Pump>R902021574 A2FO12/61L-PZP06 REXROTH AXIAL-PISTON PUMP

R902021574 A2FO12/61L-PZP06 REXROTH AXIAL-PISTON PUMP

- REXROTH

R902021574 A2FO12/61L-PZP06

- Germany

- CE ISO

- 1 pc

- contact us

- standrd package

- 5-7workdays

- Western Union,T/T

- 60 pcs

-

Anita Wu2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Anita Wu2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

Rexeoth Model list:

| Material number | Designation |

| R902018134 | AXIAL-PISTON PUMP A2FO12/61L-VPB06-S |

| R902018445 | AXIAL-PISTON PUMP A2FO12/61L-PPB06 |

| R902021574 | AXIAL-PISTON PUMP A2FO12/61L-PZP06 |

| R902021590 | AXIAL-PISTON PUMP A2FO12/61L-PAB06 |

| R902021669 | AXIAL-PISTON PUMP A2FO12/61L-PZB06 |

| R902021698 | AXIAL-PISTON PUMP A2FO12/61L-PBB06 |

| R902027137 | AXIAL-PISTON PUMP A2FO12/61L-VPB06 |

| R902027374 | AXIAL-PISTON PUMP A2FO12/61L-PPP06 |

| R902028574 | AXIAL-PISTON PUMP A2FO12/61L-XAB06-S |

| R902042055 | AXIAL-PISTON PUMP A2FO12/61L-VBB06-S |

| R902049387 | AXIAL-PISTON PUMP A2FO12/61L-VZB06 |

| R902080561 | AXIAL-PISTON PUMP A2FO12/61L-VAB06 |

| R902161395 | AXIAL-PISTON PUMP A2FO12/61L-VBB06 |

| R902193349 | AXIAL-PISTON PUMP A2FO12/61L-PZB06 |

| R902193373 | AXIAL-PISTON PUMP A2FO12/61L-PZB06 |

| R902193567 | AXIAL-PISTON PUMP A2FO12/61L-VPB06 |

| R902193750 | AXIAL-PISTON PUMP A2FO12/61L-PZB06-S |

| R902198198 | AXIAL-PISTON PUMP A2FO12/61L-PAB06-S |

| R902201651 | AXIAL-PISTON PUMP A2FO12/61L-VPB06 |

| R902201803 | AXIAL-PISTON PUMP A2FO12/61L-PAB06-S |

| R902201812 | AXIAL-PISTON PUMP A2FO12/61L-PPB06-S |

| R902201838 | AXIAL-PISTON PUMP A2FO12/61L-PPB06-S |

| R902201865 | AXIAL-PISTON PUMP A2FO12/61L-PZB06-S |

| R902204889 | AXIAL-PISTON PUMP A2FO12/61L-PZB06-S |

| R902205888 | AXIAL-PISTON PUMP A2FO12/61L-VPB06 |

| R902215368 | AXIAL-PISTON PUMP A2FO12/61L-VPB06 |

| R902237452 | AXIAL-PISTON PUMP A2FO12/61L-VPB06 |

| R902250990 | AXIAL-PISTON PUMP A2FO12/61L-VAB06 |

| R902255690 | AXIAL-PISTON PUMP |

R902021574 A2FO12/61L-PZP06 Technical data:

| Size | 5 | 10 | 12 | 16 | 23 | 28 | 32 | 45 | 56 | 63 | |||

| Displacement | Vg | cm³ | 4.93 | 10.3 | 12 | 16 | 22.9 | 28.1 | 32 | 45.6 | 56.1 | 63 | |

| geometric, per revolution | |||||||||||||

| Nominal pressure | pnom | bar | 315 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| Maximum pressure | pmax | bar | 350 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | |

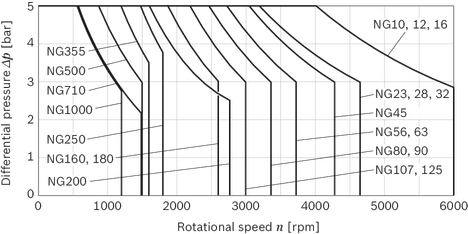

| Maximum speed | nnom 1) | rpm | 5600 | 3150 | 3150 | 3150 | 2500 | 2500 | 2500 | 2240 | 2000 | 2000 | |

| nmax 2) | rpm | 8000 | 6000 | 6000 | 6000 | 4750 | 4750 | 4750 | 4250 | 3750 | 3750 | ||

| Flow | at nnom | qV | l/min | 27.6 | 32 | 38 | 50 | 57 | 70 | 80 | 102 | 112 | 126 |

| Power | at nnomand pnom | P | kW | 14.5 | 22 | 25 | 34 | 38 | 47 | 53 | 68 | 75 | 84 |

| Torque 3) | at pnom | M | Nm | 24.7 | 66 | 76 | 102 | 146 | 179 | 204 | 290 | 357 | 401 |

| Rotary stiffness | c | kNm/rad | 0.63 | 0.92 | 1.25 | 1.59 | 2.56 | 2.93 | 3.12 | 4.18 | 5.94 | 6.25 | |

| Moment of inertia for rotary group | JTW | kg·m² | 0.00006 | 0.0004 | 0.0004 | 0.0004 | 0.0012 | 0.0012 | 0.0012 | 0.0024 | 0.0042 | 0.0042 | |

| Maximum angular acceleration | ɑ | rad/s² | 5000 | 5000 | 5000 | 5000 | 6500 | 6500 | 6500 | 14600 | 7500 | 7500 | |

| Case volume | V | l | 0.17 | 0.17 | 0.17 | 0.2 | 0.2 | 0.2 | 0.33 | 0.45 | 0.45 | ||

| Weight (approx.) | m | kg | 2.5 | 6 | 6 | 6 | 9.5 | 9.5 | 9.5 | 13.5 | 18 | 18 | |

Maximum speed

| 1) | These values are valid at: - an absolute pressure of pabs = 1 bar at suction port S - for the optimum viscosity range from vopt = 36 to 16 mm2/s - with hydraulic fluid based on mineral oils |

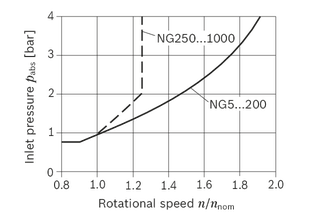

| 2) | Maximum speed (limiting speed) with increased inlet pressure pabs at suction port S, see the following diagram. |

| 3) | Torque without radial force, with radial force see table "Permissible radial and axial forces of the drive shafts" |

Note

- The values in the table are theoretical values, without consideration of efficiencies and tolerances. The values are rounded.

- Exceeding the maximum or falling below the minimum permissible values can lead to a loss of function, a reduction in operational service life or total destruction of the axial piston unit. Other permissible limit values, such as speed variation, reduced angular acceleration as a function of the frequency and the permissible angular acceleration at start (lower than the maximum angular acceleration) can be CONTACT US.

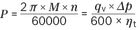

| Determining the operating characteristics | ||

| Flow |

| [l/min] |

| Torque |

| [Nm] |

| Power |

| [kW] |

| Key | |

| Vg | Displacement per revolution [cm3] |

| Δp | Differential pressure [bar] |

| n | Rotational speed [rpm] |

| ηv | Volumetric efficiency |

| ηhm | Hydraulic-mechanical efficiency |

| ηt | Total efficiency (ηt = ηv • ηhm) |

Hydraulic fluids

The axial piston unit is designed for operation with mineral oil HLP according to DIN 51524.

Application instructions and requirements for hydraulic fluids should be taken from the following data sheets before the start of project planning:

90220: Hydraulic fluids based on mineral oils and related hydrocarbons

90221: Environmentally acceptable hydraulic fluids

90222: Fire-resistant, water-free hydraulic fluids (HFDR, HFDU)

90223: Fire-resistan, water-containing hydraulic fluids (HFAE, HFAS, HFB, HFC)

90225: Restricted technical data for operation with fire-resistant hydraulic fluids

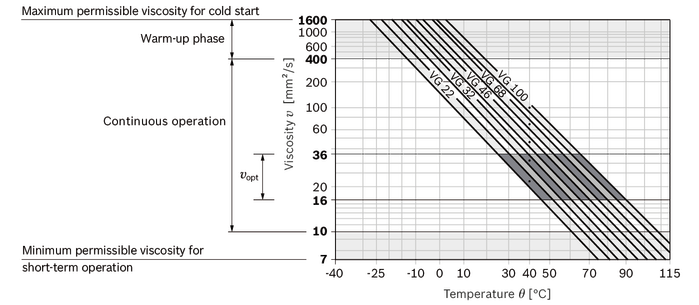

Viscosity and temperature of hydraulic fluids

|

| Viscosity | Shaft | Temperature1) | Comment |

| Cold start | νmax ≤ 1600 mm²/s | NBR2) | ϑSt ≥ -40 °C | t ≤ 3 min, without load (p ≤ 50 bar), n ≤ 1000 rpm, |

| FKM | ϑSt ≥ -25 °C | |||

| Warm-up phase | ν = 400 … 1600 mm²/s |

| t ≤ 15 min, p ≤ 0.7 • pnom and n ≤ 0.5 • nnom | |

| Continuous operation | ν = 10 … 400 mm²/s3) | NBR2) | ϑ ≤ +78 °C | measured at port T |

| FKM | ϑ ≤ +103 °C | |||

| νopt = 16 … 36 mm²/s | range of optimum operating viscosity and efficiency | |||

| Short-term operation | νmin = 7 … 10 mm²/s | NBR2) | ϑ ≤ +78 °C | t ≤ 3 min, p ≤ 0.3 • pnom measured at port T |

| FKM | ϑ ≤ +103 °C |

| 1) | If the specified temperatures cannot be maintained due to extreme operating parameters, please contact us. |

| 2) | Special version, please contact us. |

| 3) | Equates e.g. with the VG 46 a temperature range of +5 °C to +85 °C (see selection diagram) |

Explanatory note regarding the selection of hydraulic fluid

The hydraulic fluid should be selected such that the operating viscosity in the operating temperature range is within the optimum range (vopt see selection diagram).

Selection diagram

Filtration of the hydraulic fluid

Finer filtration improves the cleanliness level of the hydraulic fluid, which increases the service life of the axial piston unit.

A cleanliness level of at least 20/18/15 is to be maintained according to ISO 4406.

At a hydraulic fluid viscosity of less than 10 mm²/s (e.g. due to high temperatures in short-term operation) at the drain port, a cleanliness level of at least 19/17/14 according to ISO 4406 is required.

For example, the viscosity is 10 mm²/s at:

- HLP 32 a temperature of 73°C

- HLP 46 a temperature of 85°C

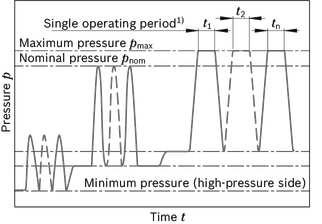

Operating pressure range

| Pressure at working port A or B (high-pressure side) | Definition | ||

| Nominal pressure | pnom | see table of values | The nominal pressure corresponds to the maximum design pressure. |

| Maximum pressure | pmax | see table of values | The maximum pressure corresponds to the maximum operating pressure within the single operating period. The sum of the single operating periods must not exceed the total operating period. |

| Single operating period | 10 s | ||

| Total operating period | 300 h | ||

| Minimum pressure | pHP min | 25 bar | Minimum pressure on high-pressure side (port A or B) required to prevent damage to the axial piston unit. |

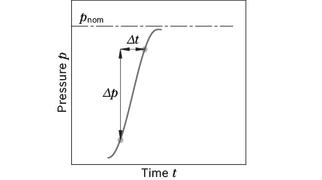

| Rate of pressure change | RA max | 16000 bar/s | Maximum permissible rate of pressure build-up and reduction during a pressure change over the entire pressure range. |

| Pressure at suction port S (inlet) | Definition | ||

| Minimum pressure | ps min | 0.8 bar absolute | Minimum pressure at inlet (suction port S) that is required to avoid damage to the axial piston unit. The minimum required pressure is dependent on the speed of the axial piston unit. |

| Maximum pressure | ps max | 30 bar absolute | |

| Case pressure at port T | Definition | ||

| Continuous differential pressure | ΔpT cont | 2 bar | Maximum averaged differential pressure at the shaft seal (case to ambient) |

| Maximum differential pressure | ΔpT max | see diagram "Maximum differential pressure at the shaft seal" | Intermittent differential pressure at the shaft seal (permitted at reduced speed) |

| Pressure peaks | pT peak | 10 bar | t < 0.1 s |

Note

- Working pressure range valid when using hydraulic fluids based on mineral oils. Values for other hydraulic fluids, please contact us.

Pressure definition

| 1) | Total operating period = t1 + t2 + ... + tn |

Rate of pressure change

Maximum differential pressure at the shaft seal

Note

- The service life of the shaft seal is influenced by the speed of the axial piston unit and the case pressure.

- The service life decreases with an increase of the mean differential pressure between the case and the ambient pressure and with a higher frequency of pressure spikes.

- The case pressure must be equal to or higher than the ambient pressure.

Direction of flow

| Direction of rotation, viewed on drive shaft | clockwise | counter-clockwise |

| Direction of flow | S to B | S to A |

Notes for sizes 250 ... 1000:

- In case of radial forces limited performance data is valid. Please contact us.

- In case of axial forces during operation of the unit please contact us.

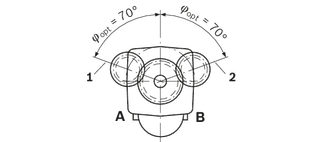

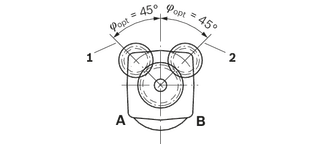

Effect of radial force Fq on the service life of bearings

By selecting a suitable direction of radial force Fq the load on the bearings caused by the internal rotary group forces can be reduced, thus optimizing the service life of the bearings. Recommended position of mating gear is dependent on direction of rotation. Examples:

Toothed gear drive, size 5 … 180

Toothed gear drive, size 200 … 1000

| 1 | Direction of rotation "clockwise", pressure at port B |

| 2 | Direction of rotation "counter-clockwise", pressure at port A |

Long-life bearing

Size 250 to 1000

For long life cycle and use with HF hydraulic fluids. Identical external dimensions as design with standard bearing. Subsequent modification to long-life bearing is possible. Bearing and housing flushing via connection U is recommended.

Bearing flushing

Flushing flow (recommended)

| Size | 250 | 355 | 500 | 710 | 1000 | |

| Flushing flow qv | l/min | 10 | 16 | 16 | 16 | 16 |

Thanks for your interesting~

Please tell me the bearing code number, dimension, drawing, or pictures?

How many sets want buy?

It will be help us confirm and offer to you correctly.

If you have any other inquiries welcome send me together.

we not only supply bearing,but also sell:oil seals,washer,lubricator,bearing ball,hydraulic pump and accessories.

Contact Us

- LOYAL MACHINERY PARTS COMPANY

- Email[email protected]

- AddressNathan 25-26, Tsimshatsui Kowloon Hongkong

- Phone(Working Time)00852-9518 9139

- WhatsApp+8615315583779

Related News

| Research on Electro-hydraulic Proportional Control Variable Mechanism of Axial Piston Hydraulic Pump |

| Self-adaptive Lubrication Characteristics of Conical Flow Distribution Pairs of Ball-piston Hydraulic Pumps |

| Modular Hydraulic Piston Pump Automatic Device |

R902218640 A7VO80LRH1/63R-NZB01 REXROTH AXIAL-PISTON PUMP

R902218640 A7VO80LRH1/63R-NZB01 REXROTH AXIAL-PISTON PUMP R902097362 AA4VG40DA1D8/32R-NUC52FXX5ST-S REXROTH AXIAL-PISTON PUMP

R902097362 AA4VG40DA1D8/32R-NUC52FXX5ST-S REXROTH AXIAL-PISTON PUMP J-V23A3RX-30 Daikin Piston Pump

J-V23A3RX-30 Daikin Piston Pump R902137627 A2FE125/61W-VAL100 GERMANY REXROTH AXIAL-PISTON MOTOR

R902137627 A2FE125/61W-VAL100 GERMANY REXROTH AXIAL-PISTON MOTOR